PureCycle Technologies (PCT) offers the only patented process for recycling polypropylene (PP) that separates color, odor, and other contaminants from plastic waste to transform it into ultra-pure recycled resin, explains Nick Hodge, editor of the Family Office Newsletter.

Around 16 billion pounds of polypropylene waste is generated each year just in the US. Around two billion pounds of it is incinerated. Just 0.1 billion pounds are recycled.

This is not the polyethylene (PET) that’s used for water bottles and detergent containers. Polypropylene is stiffer and more resistant to heat. It’s what plastic chairs, baby bottles, Tic Tac lids, and plastic utensils are made of. And it’s largely unrecyclable.

PureCycle’s process changes that. The company is constructing its first commercial plants right now. It did expect to be in production this year, but supply chain issues have delayed first production until early 2023, which is one reason the stock has drifted lower to a level I’m comfortable entering.

The first facility will be in Ironton, Ohio. The latest guidance says the facility will be complete and producing recycled pellets in Q1 2023. When fully ramped up it will recycle 100 million pounds of PP per year, which is the equivalent of what the entire US now recycles annually. It is expected to be fully ramped up by Q4 2023.

Four lines are planned in Augusta, Georgia with the first two expected to come online in the second half of 2024. Lead times for equipment are up to 90 weeks and the company expects to close debt financing for these facilities by the end of the year. These delays have also weighed on the stock. Nonetheless, offtake for these first two lines are already oversubscribed by 11%.

It is expanding globally as well. Last month, PureCycle signed an agreement to create a 50/50 joint venture with SK geo centric (SKGC) in South Korea. They will jointly create a plant there with an annual capacity of 130 million pounds. It’s also working with Mitsui in Japan on structuring an agreement and selecting a site. A European project is next on the docket.

It is securing feedstock in part through a program it developed called PureZero, where it partners with entertainment and sports venues to close the loop on their plastic waste. It has already partnered with the Cincinnati Bengals, Cleveland Browns, Jacksonville Jaguars and Orlando Magic to do this. Feedstock for the first plant is 100% secured.

Prices vary for the finished product from ~$0.50 to ~$1.00 per pound. That would peg the Ironton facility at $50-$100 million in annual revenue. By 2025, with the facilities announced so far, that would ramp to $500 million or more.

The company raised $250 million at $7.00 per share earlier this year to execute on its plans. Management, long-term shareholders, and SKGC participated in that round. It currently has $416 million in total liquidity, including $215 million in cash and $201 million of restricted cash already allocated to projects.

The company currently has 163.5 million shares out that trade at $6.50, giving it a market cap of ~$1 billion. Shares were as high as $35 in the speculative SPAC mania of 2021.

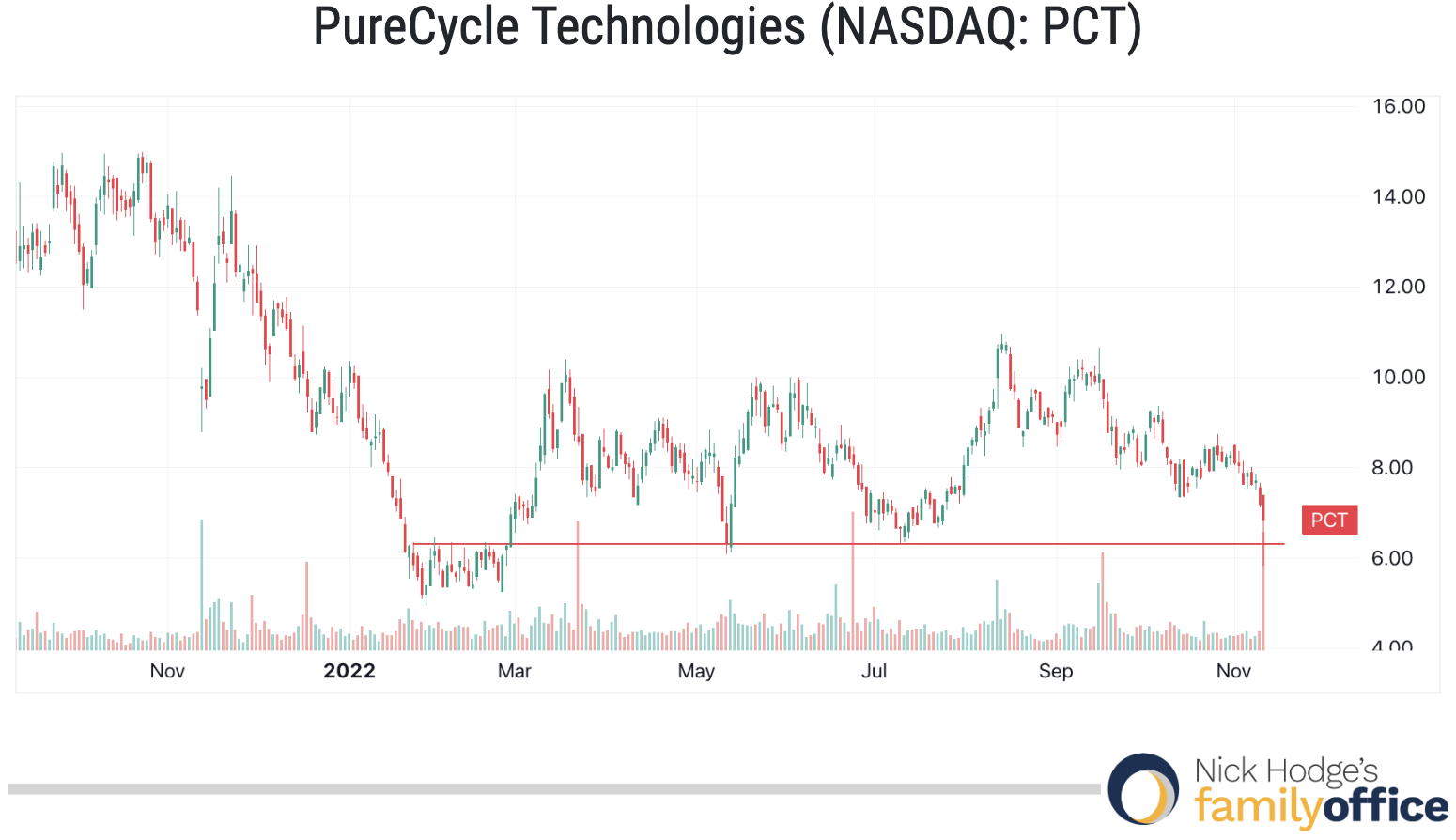

I have been watching this one for a while and began buying shares at higher prices. An earnings-induced selloff this week has revealed a price that I believe it’s now worth telling you about. They sold off hard this week after the aforementioned delays were announced as part of the quarterly report.

I believe building a speculative position below $6.30, a price I think you’ll see again in the next few weeks, will pay off over the next few years as its plants come online. Buy PureCycle by scaling in, starting with an initial purchase set at a limit of $6.30.